SCM is presenting cutting-edge solutions

SCM, a global leading producer of secondary woodworking machinery, will be displaying a cutting-edge selection of its best technological solutions and services for the market at the 13th edition of IndiaWood. Some of its state-of-the-art technologies that visitors will be able to see first-hand:

The Morbidelli P200 universal CNC machining centre is designed to meet any drilling, routing and edge banding requirement. Just a few clicks enable the design and manufacture of pieces of any shape. This solution is unique in having an unrivalled price-performance ratio and in offering several advantages.

It also offers a superior quality to the edge banding unit which can process edges up to 80 mm height. Other advantages are the head borings are fitted with RO.AX spindles with greater rigidity and a rotation speed up to 8000 rpm, the 5-axes JQX electro spindle for an unparalleled finish and the FAST 14 tool change that ensures a tool change in less than 15 seconds.

The HE-PODs, which are synonymous with flexibility and innovation, bring the third dimension to the worktable surface. The machine can lift the pieces to be processed and avoid unnecessary repositioning, making the most of the worktable size and reducing production cycle times by 30%.

The MaestroEdge software is ideal to manage and optimise the entire routing, drilling and edge banding process of panels and shaped components. The application guarantees maximum simplicity, unparalleled performance levels and a considerable reduction in the production cycle times.

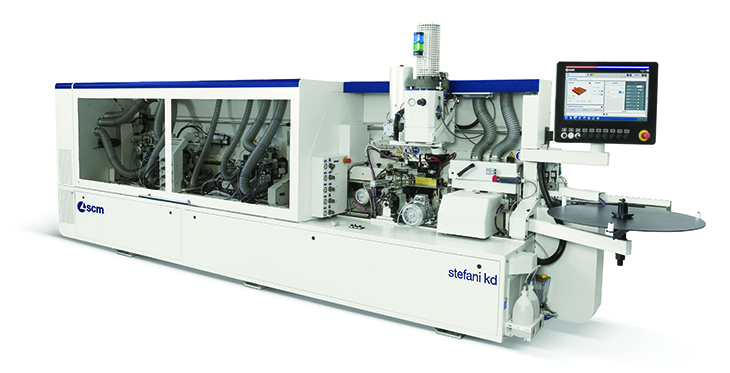

The Stefani KD is a heavy-duty and versatile edge bander for working different types of panels even with delicate surfaces thanks to the upper belt presser. A working speed of up to 20 m/min and the processing of solid wood strips up to

12 mm thick make this edge bander ideal for industrial companies that need to produce panels in large quantities and with extreme quality.

The SGP glue pot, supplied as standard, with the special non-stick plasma treatment allows the use of two different types of glue, EVA and PUR, for perfect edge banding quality even on the latest generation panels.

The optimal glue dosage and the special spreading roller ensure a perfect glue line. The SGP glue pot can be loaded both manually and with automatic pre-melters and the glues can be interchanged thanks to the automatic glue change/cleaning cycle with unloading onto the removable collection box.

The possibility of having two pre-melters at the same time, the QMS-P for EVA glue and the PU BOX L for PUR glue, always guarantees the best glue quality.

The DMC SD70 is a high-tech sanding solutions that is ideal for small-size manufacturers who look for effectiveness, efficiency and a high level of versatility and is perfect for different types of machining.

In the furniture sector, this wide belt sander is ideal for calibrating MDF, plywood and solid wood as well as sanding veneered panels and finishing painted surfaces. The configurations

can vary from two or three units, combining roller, pad, super-finishing, brush units as well as a cross-belt unit.

Recently, the range has also been enhanced with new solutions that are unique such as the led bar to optimise belt wear, the interchangeable brush unit to produce different machining processes (paint, structuring, chamfering etc.) and lastly the new eye-S control panel with Maestro active interface.

Visitors will also be able to watch demos of other SCM technologies for windows and doors manufacturing, as well as joinery machines.

Comments

- Myanmar log unveils a Vishnu masterpiece

- IndiaWood 2024: Amplifying opportunities, manufacturing innovation

- Greenlam releasing new plywood collection

- Hettich will unveil ‘Magic Lights’ collection

- SCM is presenting cutting-edge solutions

- Woodtech’s state-of-the-art machines to make their debut

- E-Chain’s tenoner reduces downtime

- Goodtek planer is suitable for wood, non-metals

- Special edge profiling machines from Technik

- Italian accessories from Utturkar’s

- Dieffenbacher smart-tunes production efficiency

- Holytek to showcase rip saw, planer

- IPCO’s world-class steel belts for the WBP industry

- Yow Cherng machines offer quality and value

- TWMA steps into smart woodworking

- Customised cutters from Tong Fong

- Richfill introducing Edge Coat

- Cutting-edge, multi-shaft products from Wen Chih

- Ebco to showcase the latest in LED lights

- Lumber without cutting trees?

- Ligna on cusp of its golden jubilee

- Steel flakes add value to wood paints

- Leitz India now global production hub

- Homing in… Impressions from IndiaWood

- Felder India launches two new machines

- Japan’s Shoda unveils dust-free CNC router

- Luigi de Vito: Look forward to ‘Industry 5.0’

- Merino: Future of chipboard is here!

- Biesse poised for growth: locally, globally

- Piergiorgio Pozzo on ‘dynamic’ saw blade balance

- Dürr’s new paint supply system cuts losses

- Hafele unveils One-Touch mechanism

- Optimus and Modula range are best-in-class

- Katana sawblades slash cutting costs

- Woodtech’s top door-making solutions

- Canadian Wood celebrates World Wood Day

- Hanoi Expo to open in May

- Interzum adds Forum in Bergmano, Italy

- Pidilite Ventures launches ‘Building Bonds’

- Events Calendar

- Xylexpo opens for 4 days in May

- Glass bricks for structural walls?

- Climate partnership bats for wood in construction

- IKEA cuts CO2 footprint 12%

- Cefla aids innovation for Portuguese panel maker

- Lamello’s small efforts have big effect

- Rehau focuses on expansion, design excellence

- Leuco tools to enter India market

- Record year for US hardwood exports to India

- Andritz partners with Indian panelboard producers

- Versatile wood species from Canada

- CMT introduces DPX blades for beam saws

- Strong panels from agri waste

- Greenlam innovations grab industry recognition at Indiawood

- IKEA launches office furniture range

- SMEs given time to prepare for QCO

- Weinig buys grinding machine unit

- China’s wooden furniture exports decline

- Melanie Bockemühl joins Siempelkamp

- Dieffenbacher supplies another Cebro plant

- SawStop to release patented technology

- Blum opens new centre in Bengaluru

- EuroTech Vertriebs is now EuroTech Handling

- Park Hotels unveils novel design concept

- Siempelkamp acquires Febs SK

- Australian Panels orders new MDF line

- HNI Office opens in Hyderabad

- Venus launches design platform

- Koelnmesse plans new cooperations in Asia

- Revolutionary acrylic boards from Decolam

- Formica makes a formidable presence

- Hafele demonstrates the value of space

- Hettich’s Magic Lights is a design philosophy

- Special ‘thali’ storage from Utturkar’s

- IPCO reports excellent response

- Jai delights with several solutions

- Atemag expands CNC machining possibilities

- Italy’s SCM ready with Indian subsidiary

- Altendorf showcases top-line panel saws, edge banding machines

- Berndorf steel belts represent cutting-edge technology

- Fiamarc elevates interiors with Frontaline glass fittings

- How to go digital with design, manufacturing

- Ozone showcases its diverse range

- Unipegasus introduces interior décor range

- Stela deploys cutting-edge drying tech

- High-quality adhesives from Unicol

- Woodtech launches 3 versatile machines