AI transforming wood panel manufacturing

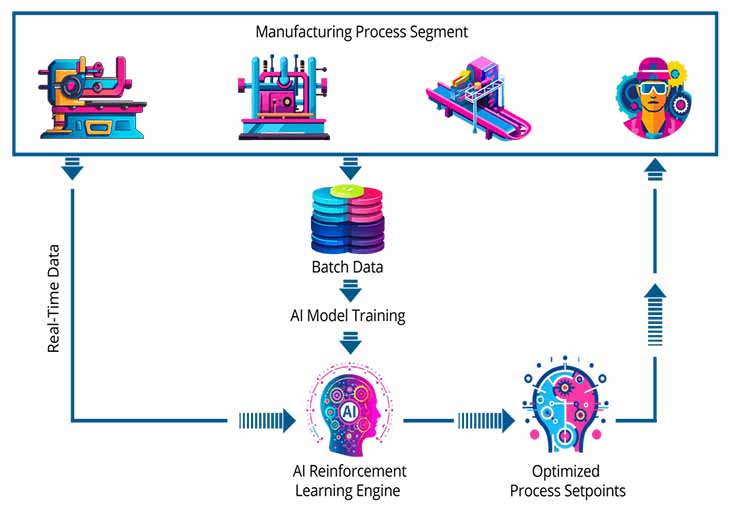

The wood panel industry is undergoing a seismic shift as artificial intelligence (AI) reshapes every layer of production, from resin formulation to real-time control of the press line.

Long dependent on operator expertise and routine interventions, manufacturing lines for OSB, MDF and particle board are evolving into autonomous ecosystems where machine learning maximises throughput, minimises waste, and stabilises production cycles.

At the forefront of this transformation is Prod-IQ∙SmartPress, a dynamic AI-driven solution co-developed by an Israeli company, Smartech, and German engineering leader, Siempelkamp.

Smartech specializes in AI-powered manufacturing technologies that optimize efficiency, sustainability, and quality across production environments. The system taps into a manufacturing plant’s operational and informational tech stack, aggregating data from machines, materials and human inputs.

Once integrated, it autonomously controls press operations, pushing real-time setpoints for higher throughput and improved board quality. The software runs continuously, learning from patterns across shifts and adjusting for variations in raw material input or equipment behaviour.

SmartPress has already been implemented across several production sites worldwide, assisting both seasoned and novice operators. Its twin-mode capability (advisory and autonomous) ensures flexibility while delivering measurable gains in consistency, speed, and quality.

In plants where SmartPress is running in autonomous mode, manufacturers have reported significant reductions in unit costs and a notable increase in production reliability.

Line focus

Parallel to the press, Smartech’s SmartForming module optimizes the forming line, which balances mat mass and speed prior to pressing. SmartForming also functions in both advisory and autonomous modes, ensuring precise coordination between upstream and downstream processes.

Its machine-learning algorithms run on-premise and synchronize operations across equipment, effectively addressing common issues like sub-optimal capacity utilization caused by asynchronous workflows.

According to Smartech’s CEO, Hanoch Magid, “SmartQuality marks another pivotal step in Hexion’s strategic transformation from a materials provider to a full-service partner delivering differentiated solutions.” His remark points to a broader industry shift where software, sensors, and materials science now converge to drive next-gen performance.

Smart manufacturing

The broader platform – branded as Autonomous MaNEWfacturing – has been developed by Smartech, whose award-winning technology is trusted by leading engineered wood manufacturers globally.

Built by experts in AI, control systems, and process engineering, the platform is designed to embed the experience of senior operators into intelligent, adaptive systems. It enables real-time optimization of equipment, reduces reliance on manual inputs, and ensures that material costs and energy use are continuously monitored and minimized.

One of the core value propositions of this platform is its ability to optimize the use of raw materials, a major cost driver in wood-based manufacturing. By predicting board quality and adjusting settings in real time, the software ensures that every input counts, without compromising output.

Comments

- European symposium highlights formaldehyde emission limits

- Egger adopts holistic approach to waste management

- ‘For customers, our lab is an open book’

- Taiwan’s Woodworking Machinery Industry Captivates Global Media on Opening Day of LIGNA 2025

- Coming of age of sustainability

- Intelligent packing line, sander from Woodtech

- Ornare introduces 5 new leather decors

- Richfill Edge Coat offers safer plywood finishing

- Jai’s Optimus range stays ahead of the curve

- Merino’s Acrolam sets new benchmarks in elegance

- Pytha 3D-CAD: where precision meets production

- Raucarp edge bands: simple, affordable

- Greenlam scores a 1st: High Quality Product Award

- Häfele turns space solutions provider

- Hettich bets on intelligent motion for evolving interiors

- Praveedh taking desi innovation to the global stage

- Turakhia shows off its Natural Veneers range

- Egger continues to ‘inspire, create, grow’

- Blum turns heads with new drawer, hinge systems

- Murubi gives American ash a meaningful life

- AR system makes ‘augmented carpentry’ possible

- Felder converts interior firm’s vision to reality

- Smart manufacturing with ‘intelligent’ tools

- Rites of passage: Craftsmanship complements tech in Indian door manufacturing

- Understanding basics of adhesives and sealants

- FFSC looks back at a decade of purpose

- Industrial-grade tools for modern manufacturing

- AWM ties up with Yeutong to boost production

- KolkataWood opens 12-14 September

- AI transforming wood panel manufacturing

- Interzum Jakarta promises a bonanza

- Expert partner in product, factory planning

- CBD Guangzhou 2025 grew 47%

- SCM hosts ‘Timber Construction Days’

- Events Calendar: Industry Fairs you must visit

- Bio-designed ‘leather’ from scrap tyres?

- HiTorc chipper redefines wood processing

- Cooking ‘veggies’ for protein-based adhesives

- Hafele’s digital locks go smart

- Italy’s Essepigi has special door lines

- Mirka is a revolution in sanding, finishing

- Ozone expands range of door hardware

- Adhesives: best practices, applications, choices

- Weber sanding tech stands up to Swiss precision

- Silent heroes in homes: Blum fittings

- Biesse powers ahead with smarter, greener manufacturing

- Homag’s LCS program ensures smooth operation

- Paged Furniture reclaims the past, shapes the future